SPRING 2003

Eliminating E-waste:

Recycling through Reverse Production

by Dr. Jane Ammons, NSF Advance Professor of Engineering, Professor of Industrial and Systems Engineering

and Sarah Banick

During the past decade, computers and new technology have revolutionized information processing. But there is a downside to what is traditionally seen as a clean industry. As our computers grow faster and more capable, we set the old ones aside for the newest model. The resulting electronic waste, or "e-waste" does not disappear so easily. In fact, it is the most rapidly growing waste problem in the world. The overwhelming quantity of e-waste is one issue, but the other critical concern is the number of toxic ingredients that are being released into our environment. Lead, beryllium, mercury, cadmium, and brominated-flame retardants pose both occupational and environmental health threats.

If you or your business are careful to recycle old computers, you may think you are not contributing to the problem. But according to the Basel Action Network, a global network of environmental activist organizations, recycling companies in Western countries simply pass the toxics on to somewhere else. Industry sources estimate that between 50 to 80 percent of the wastes collected for recycling are not recycled domestically at all. They are sent to countries like China, where poor environmental standards and low wages encourage workers to risk their health to recover the minor amounts of gold, silver, cooper, and aluminum. Despite this, the U.S. Environmental Protection Agency estimates that 12 million tons of e-waste may soon be jamming American landfields.

Among those searching for a responsible solution is Dr. Jane Ammons, ISyE NSF ADVANCE Professor of Engineering. Dr. Ammons was recently appointed to the state of Georgia's newly created Computer Equipment and Disposal Recycling Council. This board advises the Governor and legislature on potential actions and policies to enhance electronics recycling and reuse. She is also working in cooperation with the Pollution Prevention Assistance Division of the Georgia Department of Natural Resources (DNR) and the National Science Foundation on a study they hope will offer a model for other states and nations. Chemical Engineering professor Matthew Realff is also involved.

The professors are using a "reverse production" system that designs infrastructure to recover and reuse every material contained within e-wastes — metals such as lead, copper, aluminum, and gold, and various plastics, glass, and wire. Such a "closed loop" manufacturing and recovery system offers a win-win situation for everyone, meaning less of the Earth will be mined for raw materials, and groundwater will be protected. Ammons says that this simple concept requires a new way of thinking of waste as a resource. Figure 1 illustrates the key flows in forward and reverse production systems.

Figure 1. Material Flows in Forward and Reverse Production Systems

(Ammons, 2000)

Last summer, Ammons, Realff, and their graduate students presented a paper on Robust Infrastructure Design for Reverse Production Systems at the International Conference on Supply Chain Management in Beijing, China. The authors discuss the growing attention to efficiently designing and operating systems so they may handle the return flows of production wastes, packaging, and end-of-life products. The paper focuses on the strategic design of reverse supply chains that face significant uncertainty and are interwoven with the forward production chain. The driving forces for development of these complex supply networks may be financial and economic, but they are also a response to an urgent social issue.

The paper presents an approach for planning the strategic infrastructure of reverse manufacturing systems when uncertainty of key parameters is a critical issue. A mixed integer programming model is used to develop a robust solution using the criteria of minimizing the maximum regret. The approach is demonstrated using an electronics recycling case for the state of Georgia.

Case Study Overview

![]()

Electronic equipment, especially computers and televisions, is a ubiquitous part of life, with per capita ownership expected to rise for the foreseeable future. Equipment obsolescence due to technological advances such as increasing computer speed and memory, high definition television, and flat panel computer monitors will likely increase discards of these items. While much older equipment will be reused or stored for some additional years after its useful lifetime, all electronic equipment will sooner or later be discarded.

This case study is concerned with the reuse and recycling process of electronic equipment (television, computer monitors, and CPU) collected from the residential and business sectors of Georgia, with particular emphasis on avoiding the disposal of hazardous materials in landfills. The goal is to develop a fundamental understanding of how to build this infrastructure in a way that it is effective and economically viable.

The effective infrastructure of collection sites, processing sites, and transportation networks are required in order to accomplish this goal with maximum profit from a minimum budget. Data have been collected from many different sources to develop a reasonable representation for Georgia. For example, one of the non-profit organizations that helped provide model data is ReBoot, shown in Figure 2. ReBoot is a statewide, collaborative effort of many groups and organizations committed to recycling computers for people with disabilities. ReBoot acquires the equipment, evaluates it, repairs it if needed, loads licensed software, distributes the equipment to people with disabilities, and trains the person on the equipment. Currently, the organization has placed more than 4,900 recycled computer systems with disabled people throughout Georgia, the Southeast, and the United States. During Spring Semester 2003, an ISyE senior design project team was tasked to redesign the warehouse at ReBoot and to develop an inventory management system to better suit the organization's needs. The ReBoot team consists of five members working under the direction Dr. Paul Griffin, Associate Chair for Undergraduate Studies and Associate Professor in ISyE. This semester, Dr. Griffin's senior design class consists of more than 60 students and 12 individual project teams. Since 1999, ISyE students have completed 12 senior design projects at ReBoot. (If you or your company have a used computer or cell phone to donate to ReBoot, more information can be found at their website: www.gatfl.org/reboot/.)

Figure 2. Georgia Tech graduate students on a visit to ReBoot in Tucker, Georgia. ReBoot project manager Carolyn Phillips is shown fourth from left with staff and contractors. ISyE graduate students include Devon Oudit (fifth from left), Manu Sharma (third from right), Tiravat Assavapokee (second from right), and I-Hsuan "Ethan" Hong (far right).

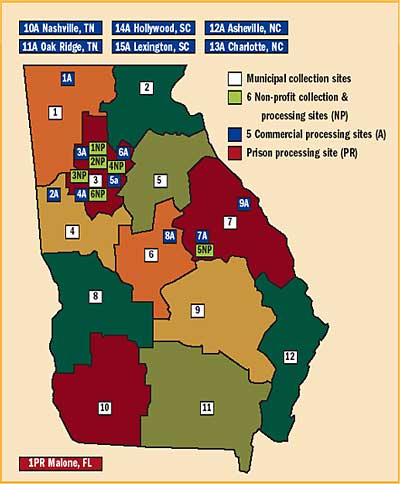

For the case study, the State of Georgia is separated into 12 different regions based on service delivery regions of Department of Community Affairs (DCA), shown in Figure 3. Representative collection and processing sites are also shown in the figure.

Figure 3: State of Georgia with Representative Processing Sites

Each region represents a source of electronic waste streams, a collection site, and a demand point for the materials after refurbishing process. The approximated amount of electronic equipment available for each source is estimated from the population in each region combined. Due to lack of space here, the parameters and information used in the model (Supply, Collecting sites, Processing sites, Demand, and Transportation information) are given in Ammons, et al. (2002).

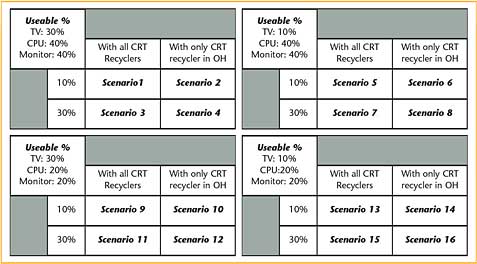

The main drivers for the system design, which are also uncertain, include the supply percentage, the options of CRT recycling, and the percentage of usability of the material collected, as well as the volume of material that will be brought in for recycling and the quality of that material. Consumer surveys indicate that about six percent of households have an item of equipment ready for disposal (Pasco County Staff, 2000). The uncertainty is how many of these households will participate in whatever collection system is put in place. We term this the percent participation, and use two potential values: 10 and 30 percent. In addition, a key uncertainty is whether the system can allow material to be shipped (at relatively high cost) to a CRT glass recycler in Ohio. In the case of electronics recycling, the quality indicator is how much of the stream can be re-used in other applications, as opposed to being junked for material value only. We term this by the percent usable, and use two levels for each product type. It is important to realize that the determination of whether or not the item is usable is made during the sorting process and hence all of the items must be collected regardless of their eventual usability. These uncertain factors were used to define 16 problem scenarios that are shown in Figure 4.

Figure 4. Sixteen Problem Scenarios for the Case Study

Case Study Solutions

![]()

The case study was solved on a Window NT-based MHz Pentium II personal computer. For solving mixed integer programming for this case study, Visual Express v12 [Dash, 1999] was used as the optimization program. MS-Access and Visual basic programming languages were used as this case study database and data-transferring program.

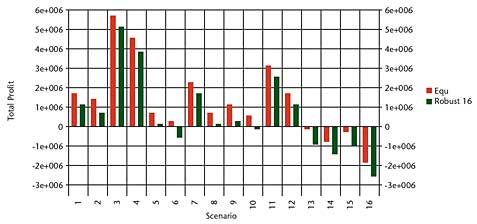

The objective function results for all scenarios under each of three model types are shown in Figure 5. It is clear from the figure that the relative collection percentage and usable percentage have a substantial impact on the net profit of the solution infrastructure, confirming intuition that the worst economic outcomes would be realized in scenarios 13 - 16. The robust solution is constructed using the methodology outlined in the paper. The performance of this solution demonstrates that it is able, with one set of infrastructure, to perform reasonably close to the optimal solution across the wide range of uncertainty. This result is encouraging, indicating that relatively better decisions can be made if attention is paid to the uncertainty.

Figure 5. Objective Function Value (Net Profit to nearest thousand) Obtained for Each of the Scenarios and for the Robust Solution

These results also point out the need to better understand how to design systems to encourage larger collection percentages and higher usability percentages. For example, collection systems that facilitate user convenience should be a goal. Also, getting equipment back while it is relatively new, before it has the chance to sit in the closet or basement and get obsolete, may require targeted marketing and education campaigns. The model can help quantify the potential benefits of these efforts.

What's Next?

![]()

Professors Ammons and Realff and their team of graduate students are working to extend and refine their models, methodology, solution approach, and databases to better understand how to design reverse production systems for electronics recycling and reuse. Insights are being shared with researchers around the world and with key officials who are in the process of designing local and regional policies to address this challenging problem. Through this work, Georgia Tech hopes to have an important impact on the environmental welfare of future generations and on the ultimate creation of "closed loop" manufacturing systems for our society.

For more information, contact Dr. Jane Ammons at [email protected]