SPRING 2004

Nature & the Industrial Enterprise

Mid-Course Correction

An Interview with Ray C. Anderson

Ray Anderson, BSIE 1956, is the founder and chairman of Atlanta-based Interface, Inc., one of the world's largest interior furnishing companies. For the last decade, he has been committed to making Interface a sustainable enterprise that consumes no non-renewable resources and produces no waste — taking nothing and doing no harm. In this interview, he speaks about the circumstances of his conversion to these beliefs, the resulting products and profits, and how he hopes to radically influence the practices of modern industry.

EE: Give us some sense of the genesis of your thinking in this area of natural systems and sustainability. Was there some key event, or driving force?

Anderson: It came out of my own life changing mid-course correction. Once I had my eyes opened by [business writer] Paul Hawken, I began to read voraciously. One thing I learned is that a forest is a very complex, self-organizing system. In fact, nature is filled with self-organizing systems. Through billions of years of evolution, nature has evolved very efficient, effective, self-organizing systems that meet all of its needs with abundance and no waste.

EE: What's the time frame for when you began your readings?

Anderson: All of this began in the summer of 1994, and evolved over the next year or two as I got myself up to speed on what was already known about sustainability and the path to sustainability. I first formed the impression that nature is a model, and then I realized that is not so — nature is the real thing, and we have, in the industrial system, a very poor artifice that needs changing. We can look to nature for the inspiration, the guiding principles to make the changes needed in the industrial system to make it as effective as nature is — waste free, resource-effective and resource-efficient, benign, operating on sunlight the way nature operates on sunlight; taking nothing and doing no harm.

I had a conversation with [former ISyE School chair] John Jarvis somewhere along the way. I said. "John, if you can figure out how a forest works, you will have a pretty good idea of what the industrial system ought to look like." At least, metaphorically you have it there. In the midst of Georgia Tech's capital campaign, I was persuaded to make a contribution, and this sort of sprang out of my head: Why not create a Chair of Natural Systems and dedicate somebody to studying nature and how to emulate nature in a sustainable, effective, efficient industrial system?

EE: Were you applying these ideas at Interface in that same timeframe?

Anderson: In a way, yes. We recognized a few of those organizing principles. In nature there is no waste, so we set out on a quest, literally QUEST — Quality Utilizing Employee Suggestions and Teamwork — to eliminate waste. When you look at a manufacturing operation, you know there is going to be a certain amount of off-quality, so you build in cost allowances for these, and you have a standard cost system that allows so much expected waste and so much off-quality and so forth. Interface has manufacturing operations all over the world, and every one had a different idea of what was standard. You couldn't compare one operation with another without getting into the question of, "How did you establish your standard?" So one day we said, "Let's just measure everybody against perfection. Let's take all the waste out of the cost, and see what our cost would be if we had no waste and no off-quality. If we did it right the first time, every time." We found 10 percent of the sales dollar was going to waste, most of it allowable under the standard cost system. So we thought, if we measure ourselves against perfection, and go after all waste, we will get further than we can ever get with a standard allowance.

EE: It is easy to imagine that practically doubling your profits.

Anderson: During the nine years we've been measuring it, the elimination of waste — the savings — represents 28 percent of our operating income, and we still have two-thirds of it yet to go. We've already captured about one-third. It gets close to doubling your profit if you can eliminate waste.

EE: We're here in the ISyE Chair's office with our feet on your Entropy carpet. Can you tell us the inspiration for this product?

Anderson: Entropy is a wonderful example of looking to nature for inspiration. Our head of product development, David Oakey, read Janine Benyus's book, Biomimicry, and he was inspired. He decided to send his entire design team into the forest. He told them, "Go, and see how nature would design a floor covering. And don't come back with leaf designs; that's not what I mean. Come back with design principles. What are nature's design principles?"

They spent a day in the forest, looking at the forest floor, looking at the streambed, and finally it dawned on them, there are no two things alike on the forest floor, or in the streambed. Each stick and every leaf is different. Yet, there is a uniformity to that chaos. Sort of organized chaos. You can pick up a stick here and drop it there, and you can't tell you've changed anything. They came back realizing that nature's design principle is basically organized chaos and total diversity. And they designed a carpet tile where no two were alike. That's what you have in Entropy.

Aside from being a very pleasant aesthetic that emulates the forest floor, it turned out to be practically waste-free in the production process. You cannot find a defect. If there is a defect, it's camouflaged by the design. The installation process has practically no waste. When the installer gets to the edge of the room and cuts the last piece to fit, the scrap from the last piece can be used somewhere else. And you can't find it; you won't recognize it as a cut carpet tile.

EE: People sometimes come into this office just to see the carpet.

Anderson: There is a woman on the speaker circuit — I can't remember her name — who begins every speech by asking her audience to close their eyes and imagine that perfect place where they feel safe and secure, creative, and totally at ease. Totally comfortable. She lets them think about it, and then she asks, "How many of you were someplace indoors?" Hardly anyone ever raises a hand. That perfect place we gravitate to is in nature. It is somewhere outdoors. I really think part of the appeal of Entropy is that it brings part of the outdoors indoors on a subliminal level. After it was introduced, it became the number one seller in the product line, faster than any other product has ever made it to the top of the league tables.

You asked me if Interface was in any way patterned after nature. When I first read Janine Benyus's book, I came to the chapter on the industrial organization and how it could be organized to simulate nature. And as I read it, it described Interface. She didn't know Interface when she wrote the book. But what she described as the industrial enterprise that is modeled after nature is Interface: the idea of cyclical processes, doing no harm to the biosphere, taking nothing from the earth that is not naturally and rapidly renewable, and producing no waste. Ultimately that is the objective, even though we have a long way to go. We want to drive the whole thing with sunlight, renewable energy, closing the loop on material flows so that you have not only the basic organic cycle we're all familiar with�the dust to dust cycle�but in an analogous way, a technical cycle that takes used-up products and gives them life-after-life through the recycling process, so that no molecules are lost; everything stays in the flow, the material loop. All of that is basically emulating nature in an industrial system, and that remains our goal. We're one-third of the way there, not only on the waste front, but in other respects, too.

One measure is carbon intensity, the amount of petroleum extracted from the earth, processed through the entire supply chain to produce a dollar of revenue for our company. Not just the material, but the energy, too. The carbon intensity of Interface is down one-third in nine years. We've managed to shut down 39 percent of our smokestacks, and 55 percent of our effluent pipes. In a number of cases, this has been done by simply eliminating processes altogether or designing around the processes to produce a waste-free, emission-free, effluent-free production line.

EE: Does Interface just happen to be naturally oriented this way, or did you have to go through some sort of transformation?

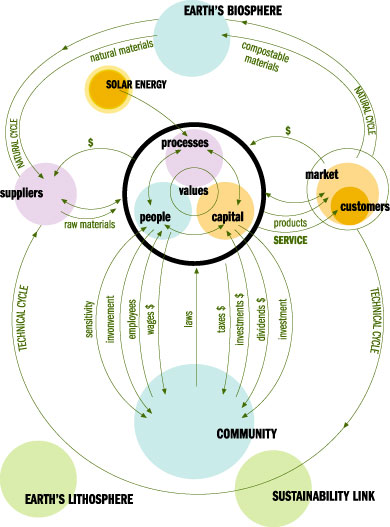

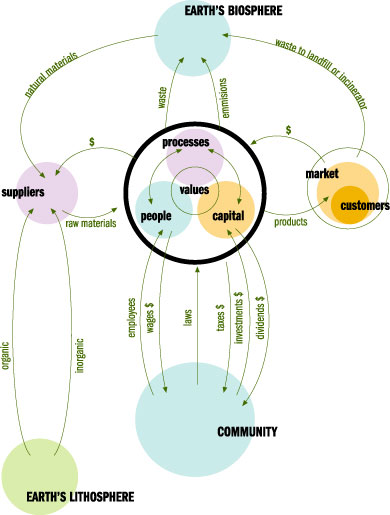

Anderson: Oh, it was a total transformation. It was a burst of insight, followed by a couple of years of really digging in and studying the literature and thinking. We drew a schematic (see Diagram X) of a typical company of the twentieth century. Then we created a series of schematics that showed the evolution to the prototypical company of the twenty-first century. We made that first schematic of our company, showing the linkages to the lithosphere (the crust of the earth), the biosphere, the supply chain, the community, the supply chain's dependence on the earth's crust, on the biosphere, and so forth. And we asked ourselves, what's wrong with this picture? Out of that came the plan for pursuing sustainability. We call it climbing Mt. Sustainability, identifying the seven faces of the mountain, and figuring out how to climb each of those seven faces to meet at the top, at that point where environmental impact, or footprint, is zero. We imagined the kinds of initiatives that would be necessary to make it to the top of each of those faces, to become the prototypical, sustainable company of the twenty-first century (See Diagram Y). All of that developed over the course of a year or two.

![]()

Diagram X: Typical Company of the 20th Century

![]()

Diagram Y: Prototypical Company of the 21st Century

![]()

EE: When you announced this to your management team and your colleagues, did everybody buy in immediately?

Anderson: People thought I was nuts. We had to go through a total cultural transformation. The culture shift still goes on, we still have people asking why, and it is nine years later. Of course, new people come and people leave, so we're constantly renewing the process of inspiring people to see the world a different way.

EE: Is it easier now, when you hire people, to get the people you want?

Anderson: My goodness, yes, it has now become a huge magnet for people who never would have thought of going to work for a carpet company. The carpet industry has a pretty poor reputation, frankly, but Interface has been able to rise above that and attract people we never would have attracted, and keep people that we never would have been able to keep involved and motivated. People want to be identified with a higher purpose.

EE: What would you say were the toughest one or two things in that transformation effort?

Anderson: It took about 50 speeches by me before we really got a lot of buy-in from our people. The toughest challenge was really to be sure that we stayed on the drum beat, the consistent, persistent message. This is where we've been, this is where we're going, and we have got to do this. Unless somebody leads, nobody will. Why not us? That was the message.

EE: You're constantly selling the idea.

Anderson: Constantly, constantly. It became my mission, my personal mission, to bring our people along, share the vision, and put it out there so clearly that they would grasp it. It requires a different way of thinking.

EE: How long did it take until it got a little easier?

Anderson: I'd say two or three years. And it was a watershed event. I was invited in August of 1995 to speak to the U.S. Green Building Council at its annual conference. I put a lot of myself into that speech; it was only my second public speech on the subject. I worked really hard on it, and it was well received, so I had it published in a tiny little booklet, which you can read in 20 minutes or less. It described my own conversion, and my vision for our company to lead the whole industrial system toward sustainability. It was distributed all through the company. Some people read it, and others didn't, I'm sure.

About six months later, I was invited to Scotland to an environmental conference to make a speech. My management team in Europe — and that's about a third of our company — found out I was coming to Scotland and asked if I'd stop and spend a day with them. They said, "We want to understand what you are really thinking." This was a year and a half into this process. They were sitting there in Europe not believing that any American company could be serious in what I was saying, because they see America, and the way we live, and they didn't believe we were serious. So they asked to see me, and I agreed to stop in London. I told them, "Yes, I mean it, this is where I want Interface to go."

Two of them wanted to go along to Scotland to hear my speech. After I spoke there was a break. The hall was vacated when I came back in. There was one person who had come with me sitting in this big room, like a cathedral. I came up behind him and looked over his shoulder, and he was reading that little pamphlet. And he looked up, and there were tears streaming down his face. He said, "You know, I've read this before, but now that I've heard you say it, I'm reading it again, and I just want you to know that I get it" After that, the European team really came aboard. And because Europe is so far ahead of us in their thinking [about the environment], it gave us a real shot in the arm back here in the U.S., to have them fully engaged, and in a way, showing us the way.

EE: You contrast human practices with nature's practices, but given that we're part of nature, why aren't our practices natural in some sense also?

Anderson: We are different from any other organism on earth in the way we take more than our share and give back our poison. The rest of nature can't handle it. We set ourselves apart from nature. We're at war with the rest of nature. You could call it a civil war. It is a war where if we win, we lose. Of course we are winning; therefore, we are losing. We're losing the biosphere at a rapid rate, in an instant of evolutionary time.

EE: I've often wondered about how much effort goes into maintaining lawns, and why? It just strikes me that there is a huge amount of effort to make the lawn look like carpet. Why do we invest all that energy?

Anderson: (laughs) So we can cut it, fertilize it and let it grow, and cut it again. I think civilization is at war with nature; since civilization is humankind's creation, that puts us at war with nature.

EE: Whereas a colony of beavers doesn't war with nature, they use nature...

Anderson: The give and take all balances out with them; it doesn't balance out with us.

EE: Who in this whole effort are your heroes?

Anderson: People primarily from the non-governmental organization (NGO) community who have been out there for years and years gaining an understanding of what is going on, sharing that understanding with us, not only finding the problems, but trying to develop the solutions. Paul Hawken, Amory Lovins, Janine Benyus, Karl-Henrik Robèrt, Daniel Quinn, Donella Meadows. They are my heroes. Lester Brown, who has been writing for the World Watch Institute all these years and producing the State of the World Report every year. He's basically been a voice in the wilderness for years, but the stuff he's saying is true. And there is an economist by the name of Herman Daly who has been saying for years that our economic system is upside down.

|

|||

EE: What happens next? You're one-third of the way there with Interface. I imagine the next pieces get tougher and tougher?

Anderson: There are some breakthroughs that will have to happen. And there are some that have happened, where we've not yet realized the total benefit. David Oakey's work with our products has only just begun to kick in, and our product line will evolve more and more in a sustainable direction, with recycled content and renewable energy. Another breakthrough that we're on the verge of is the use of carbohydrate polymers as substitutes for hydrocarbons. Hydrocarbon coming from petroleum, carbohydrates coming from vegetable matter. Cargill, the big grain grower, and Dow Chemicals have created a joint venture, Cargill Dow. They are extracting the tiny bit of dextrose from a kernel of corn, and through a bio-engineering process, producing polyester, a synthetic fiber, derived directly from corn, rather than going through billion-year-old oil — ancient sunlight — to get there. Taking today's current solar income, if you will, corn, and going directly to the synthetic fiber. We're working with this in textiles and in carpet. That's a transition that lies before us. We're in the early days.

EE: You also had some ideas about leasing carpet?

Anderson: That's gone nowhere. The market is not ready for it. The economics don't quite make sense yet because we have not closed the loop on all the material flows. You still have oil subsidized to a terrific degree, so anything made from oil is basically subsidized. You have an artificially low market price for the virgin materials; consequently, you don't have the value in the recycled material that you would have if prices were honest. Instead, we have this basically blind and dishonest marketplace.

EE: What if we included a portion of the defense budget in the oil price?

Anderson: Well, yes, the portion that is protecting the oil at its source; together with a war in the Middle East every now and then. The cost of global warming is not reflected in the price of a barrel of oil, either. You have the externalities. This is Herman Daly's theme, that the externalities don't get priced by the market. They get externalized, so you have a blind market allocating resources. It's crazy.

EE: Is that primarily in the oil area, or are there other areas?

Anderson: That's probably the most flagrant of all — the billions of dollars that go to subsidize the oil industry, including the wars in the Middle East. There is a book by Norman Myers, Perverse Subsidies: How Misused Tax Dollars Harm the Environment and the Economy, that details the perverse subsidies that we have all around us.

EE: Cotton has been getting a lot of attention lately.

Anderson: Cotton is one. Cotton is what, two percent of the total fiber production of the biosphere, and uses 22 percent of the pesticides? And a huge amount of water. Norman Myers' book details that. It'll make you cry.

EE: If someone from your research staff, or Georgia Tech, could walk into your office and say "we've just discovered how to do x," and it is something plausible, what would help you most?

Anderson: Closing the loop on nylon type 6,6. Type 6,6 is the designation for the polyamide molecule that we know as nylon. There is another one, type 6 (and that has to do with the number of carbon atoms in the molecule). Nylon 6 is recyclable; nylon 6,6 is not. Nylon 6,6 is the better fiber in terms of durability and wear and all those good performance attributes. So the best product for its functional value is the hardest to recycle. Du Pont, who makes the type 6,6 nylon, has basically given up on the recycling of it.

EE: What are your thoughts about students' orientation toward this whole topic? Have you seen that change over the years?

Anderson: Not much, yet, because you guys are still teaching the wrong stuff. You go to the mechanical engineering school and your students are still learning about internal combustion engines instead of fuel cells. You go to ceramics, and people are still studying heat, beat, treat technology for producing ceramics, instead of studying how the abalone does it better out of commonly available minerals in the ocean at 40 degrees Fahrenheit. Economic students are still learning a system of economics that allows the externalities and ignores those subsidies as if they were deserved. The education system needs revamping. You're teaching the wrong stuff, which is why I'm on your case all the time. You're still teaching the system that is destroying the biosphere, and teaching the teachers to perpetuate it.

EE: Why do you think we do this? One reason could be that education is just an inherently conservative enterprise and changes very slowly. Or maybe there are other reasons?

Anderson: I think there is an entrenched commitment to the status quo. It is like there is a vested interest in the status quo. Why does education change so slowly? That's a really good question. It is the most ponderous of institutions.

EE: Yes, we got the basic disciplinary organization back in Bologna in 1119 and we're hesitant to change it.

Anderson: You've got a lot of silos, too. People don't want to look across the silos at what the other guy is doing because it might make doing what they do wrong.

EE: Another possibility is that you can't really appreciate this phenomenon unless you look at it from a multidisciplinary point of view.

Anderson: That's another point that Herman Daly makes in his book For the Common Good. It is an absolutely wonderful read. I recommend it to anyone in education.

EE: We've got various initiatives trying to enhance the multidisciplinary activities at Tech, but you really have to work at them to make them succeed. And that's true at all universities. Any other observations? Your thoughts now as compared to 10 years ago? Any surprises?

Anderson: When we began this initiative, we stumbled upon waste elimination as the first face of the mountain, the first priority, the initiative that, if we tackled it first, would pay the way for all the rest. That's still basically true. We continue to whittle away at this waste opportunity. We continue to generate savings that are paying for investments we are making in research and development. In more recent years, a couple of allies or partners have developed to help pay for this whole journey.

The first of these is the goodwill in the marketplace, which should not be underestimated. People are looking for authenticity in an artificial world. Our customers, particularly the interior design community and architects, are people who just want to do the right thing, if someone will only show them what that is. They have embraced what we have done, and that has translated directly into the good will of the marketplace and a predisposition to deal with Interface. That's not everybody, but it is unquestionably a segment of the market place, and it has cushioned our top line in a very bad recession.

Our industry is down 40 percent from five years ago. Our own sales are down 26 percent; but in a marketplace that's down 40 percent, we have gained market share in a recession. Just now, the products out of this pursuit of sustainability are beginning to emerge, products like Entropy. And now there is a family of products built on that basic principle of diversity. In our fabrics business, we are using more and more recycled content. Something like 87 percent of our raw materials in that business now come from recycled PET, primarily Coke bottles. The products have begun to kick in along with the customer goodwill, so you've got a positive feedback loop building.

EE: This is an example of doing well by doing good?

Anderson: This is doing well by doing good. As the resource efficiency improves, and we get some help from the economy, which finally looks like it is coming, I believe that we will become the example that the whole sustainability community has been waiting for. Finally a company emerging that is really doing well at the same time. I think that example will attract other companies. I know it has moved our whole industry already. Every competitor is on our heels.

EE: Are they pushing for the same sustainability issues, or are they doing it different ways?

Anderson: They are all reacting to our initiative in their own way. Typically, it is a product here and a product there. We've not seen anybody else take the whole, broad, seven-faces-of-the-mountain approach to this. But everybody is doing something, and consequently you have an industry that is moving toward...glacially, but moving toward...sustainability. If we could do that to the whole industrial world, by setting the example for others to emulate, that would really be significant.

Toward Sustainability:

Ray Anderson's Suggested Bibliography

for the Enlightened Industrialist

![]()

Benyus, Janine. Biomimicy: Innovation Inspired by Nature. Perennial Publishers, 2002.

Carson, Rachel. Silent Spring. Houghton Mifflin Company, 1993.

Daly, Herman, and John Cobb. For the Common Good. Beacon Publishers, 1994.

Hawken, Paul. The Ecology of Commerce: A Declaration of Sustainability. Harper Business, 1994.

Myers, Norman, and Jennifer Kent. Perverse Subsidies: How Misused Tax Dollars Harm the Environment and the Economy. Island Press, 2001.

Quinn, Daniel. Ishmael. Bantam Books, 1993.

Those interested in reading more about Mr. Anderson's philosophy and how it applies to Interface may wish to read his book, Mid-Course Correction, 1998, distributed by Chelsea Green, and available at Barnes & Noble and amazon.com.

![]()

![]()

![]()

• Spring 2004 Engineering Enterprise Table of Contents

• Engineering Enterprise Home Page

![]()

![]()

![]()

Web Site © Copyright 2020 by Lionheart Publishing, Inc. and ISyE, Georgia Institute of Technology. All rights reserved. No portion of this publication may be reproduced in any form without the written permission of the publisher.

![]()

![]()

Lionheart Publishing, Inc.

34 Hillside Ave

Phone: +44 23 8110 3411 |

E-mail:

Web: www.lionheartpub.com

![]()

ISyE / Georgia Institute of Technology

Atlanta, GA 30332-0205

|

Web: www.isye.gatech.edu